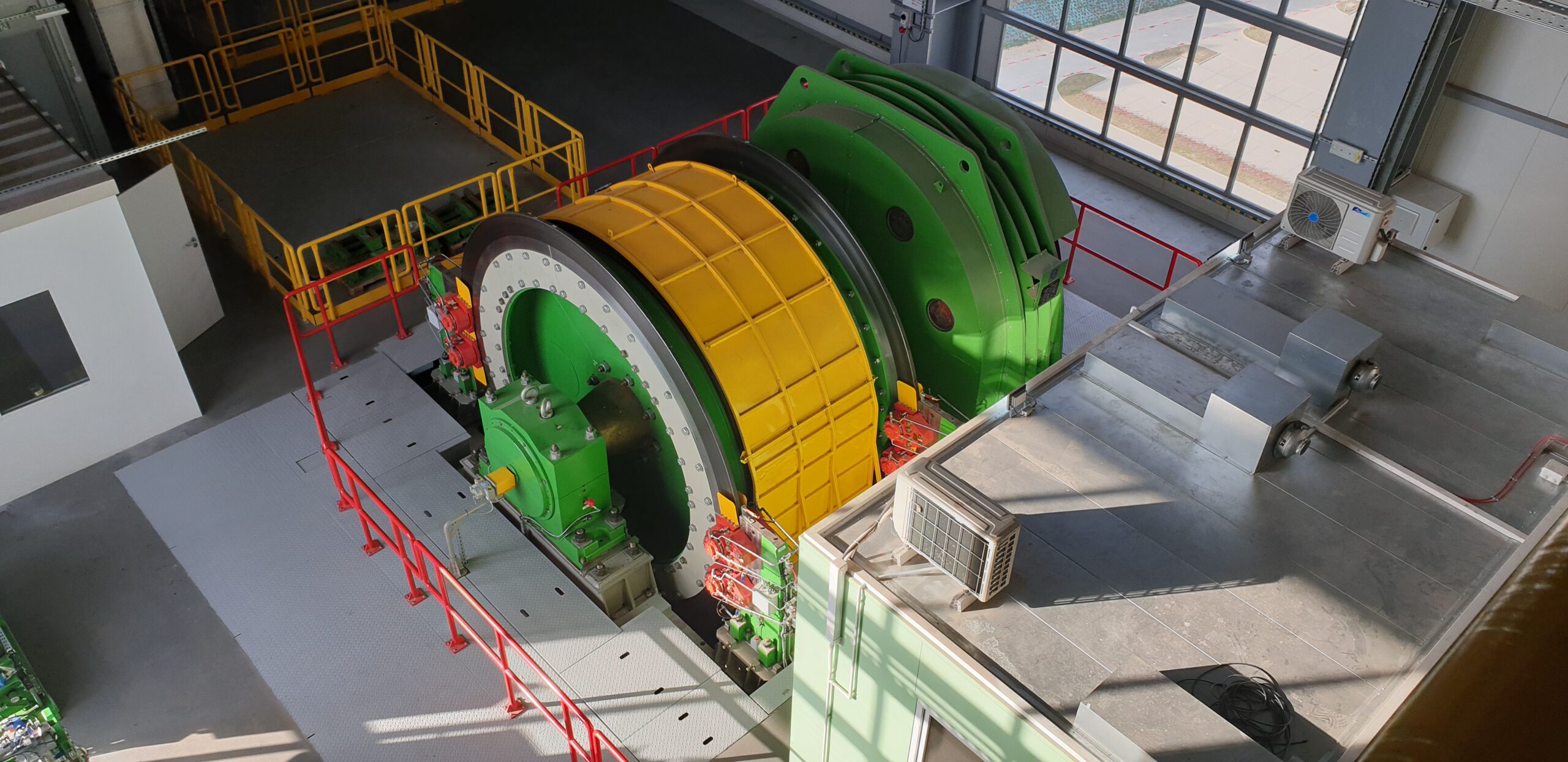

The main components of the hoisting machine are:

- drive motor,

- primary shaft with bearings and winder,

- brake with hydraulic opening cylinders,

- converter transformers of the primary circuit, excitation and auxiliaries,

- primary and excitation converters,

- control, monitoring and safety systems,

- system for the visualisation and signalling of the operating states of individual components of the hoisting machine.

Type 4L-3600/DC-12m/s primary hoisting machine is based on a foundation that is part of the shaft headframe structure, and the primary shaft unit with spherical roller bearings is embedded in bearing housings. A novel hydraulic seating of the hub on the tapered journal of the primary shaft was used to house the rotor of the drive motor.

The braking process is carried out by a set of eight pairs of BSFG 408-type brake cylinders with hydraulic opening, and the brake cylinders are powered by an electro-hydraulic control and power unit H-C MWM-4/VER.III (dual system).

The drive drum of the hoisting machine is directly driven by a 2400 kW foreign-built DC motor, which is powered by two ABB DCS800 series non-reversible thyristor converters connected in series (simultaneous and sequential control). The motor excitation circuit is powered by a DCS800 series reversible converter (full reserve).

The machine is adapted to be powered from the 6 kV grid through two 6/0.5 kV converter transformers, with connection groups that allow operation with 12-pulse drive interaction with the grid. In the event of a failure in the power circuit of one of the thyristor converters of the primary circuit, there is the possibility of emergency operation using the second converter included in the described power circuit. In this state, the speed reached by the machine is reduced by half, but there is no limitation on the lifting capacity.

The hoisting machine uses the GRZ-08 digital travel controller, which has been used in multiple mining shaft hoists such as Koepe pulley double-tub hoists and winding drum double-tub hoists. It simultaneously acts as a complete speed control system.

The entire control, regulation and protection systems are based on programmable controllers and other components produced by reputable companies.

All relevant functions displaying the operating states of the hoisting machine are included in the on-screen visualisation system.

The hoisting machine works with the newly installed shaft signalling and communications equipment, communicating with it in two paths, by electrical connections and through communication links.

Technical data of the type 4L-3600/DC-12m/s hoisting machine:

| number of hoisting ropes |

4 |

| winding diameter of the hoisting ropes on the winder |

3600 mm |

| maximum speed |

12 m/s |

| nominal diameter of the hoisting rope |

41 – 44 mm |

| static overload |

150 kN |

| power supply parameters: |

|

| hoisting machine |

6 kV, 500 VAC |

| auxiliary circuits |

500 VAC, 230 VAC, 24 VDC |

| primary parameters of the drive motor: |

|

| type |

PW-124 |

| power |

Pn = 2400 kW |

| RPM |

nn = 64 rpm |

Signalling and communication device of the mine shaft hoist in the cage compartment

The shaft signalling and communication device, based on PLC programmable logic controllers, is designed to operate the primary shaft hoist and is equipped with the ECHO-S wireless shaft communication device and the TS type local shaft telephone communication system.

The device has signal stations built in the operator’s cab, the shaft headframe, on the shaft entry, at the level of the shaft inlet, in the shaft sump, as well as non-stationary stations in the hoisting tubs, for completing all the tasks of the mine shaft hoist.

The device is powered by two 230 VAC power sources with backup in case of a power outage.

Communication links between local stations are implemented using optical fibre cables as two independent transmission paths, each made as a closed loop.

B-1200/AC-2m/s type hoisting machine

The B-1200/AC-2m/s type hoisting machine is a component of a single-end mining emergency and inspection shaft hoist in the L-VI shaft.

The shaft hoist is provided for:

- evacuation of personnel from the tub of the primary hoist stopped in the shaft by emergency or from the levels,

- inspection of the technical condition of the shaft, repair of shaft equipment and shaft works.

The control of the hoisting machine is manual from the hoisting machine control panel or automatic in remote start mode with speed control.

The hoisting machine is equipped with a 132 kW AC motor that, together with the drive system, allows the hoisting tub to move at a speed of 2 m/s.

The primary components of the B-1200/AC-2m/s hoisting machine are:

- primary shaft unit, which is supported in two roller bearings, with a winding drum equipped with a LEBUS liner suitable for a hoisting rope of nominal diameter 22 mm,

- cylindrical toothed gear with a gear ratio of 45,

- 132 kW AC motor,

- disc brake, which consists of 2 pairs of hydraulic opening cylinders type BSFG 408, mounted on two brackets, controlled by an electro-hydraulic control and power unit H-C MWM-6D implementing dual emergency braking and a device for forcing additional oil drainage,

- ACS800 series frequency converter powering the hoisting machine drive motor, enabling motor or generator operation,

- 500 VAC switchgear for powering the frequency converter and auxiliary drives of the hoisting machine,

- control, adjustment and safety systems of the hoisting machine, along with the systems of informational signalling of the operating states of the various components of the hoisting machine.

Technical specifications of the B-1200/AC-2m/s hoisting machine:

| winding diameter of the hoisting rope in the first layer |

1200 mm |

| number of layers of hoisting rope |

7 |

| nominal diameter of the hoisting rope |

22 mm |

| maximum static force in the hoisting rope |

60 kN |

| hoisting depth |

1200 m |

| maximum speed |

2,0 m/s |

| acceleration/deceleration |

0,6 m/s2 |

| power supply parameters: |

|

| hoisting machine |

6 kV, 500 VAC |

| auxiliary circuit |

500 VAC, 230 VAC, 24 VDC |

| power supply parameters: |

|

| type |

M3BP 315 SMB 4 |

| power |

Pn = 132 kW |

| RPM |

nn = 1486 rpm |

Signalling and communication device of the emergency/inspection mine shaft hoist

The shaft signalling and communication device, based on PLC programmable logic controllers, is designed to operate the emergency/inspection shaft hoist and is equipped with the ECHO-S wireless shaft communication device and the TS type local shaft telephone communication system.

The device has signal stations built in the operator’s cab, the shaft headframe, on the shaft entry, at the level of the shaft inlet, as well as non-stationary station in the hoisting tubs, for completing all the tasks of the mine shaft hoist.

The device is powered by two 230 VAC power sources with backup in case of a power outage.

Communication links between local stations are implemented using optical fibre cables as two independent transmission paths, each made as a closed loop.

6 kV RMW switchgear

The switchgear has been installed in the shaft headframe building in a separate confined space for electrical operation.

The 6 kV RMW switchgear is a 7-bay switchgear based on e2ALPHA type switching bays. In addition, the cabinets constituting the auxiliaries bay of the switchgear were installed.

The switchboard is equipped with the following circuits:

- auxiliaries of the switchgear,

- controls, interlocks and signalling,

- protection of the primary switching bay,

- communication of safety devices,

- arc protection,

- control and measurement.

Active higher harmonic filter

The active higher harmonic filter consists of:

- active higher harmonic filter of the type IC-SinVar-400.400-16.1,

- IC-PowerMan-16.1 active filter control system.

Power supply to the filter is provided from the RMW switchgear bay through a special design transformer 6/0.4 kV.

For the active filter, the IC-PowerMan-16.1 control system was installed, an integral part of which are the PM175 and PM130EH power quality analysers installed in the RMW switchgear bays. The system converts measurement signals from current transformers, voltage transformers and bay controllers from selected medium-voltage bays.

Video monitoring

The modernisation of the video monitoring, as an operator support system, consisted of:

- installing cameras on the shaft entry and inlet of the LVI shaft,

- expansion of optical fibre infrastructure,

- installation of transmission units,

- installation of IT infrastructure (servers, operator stations and software).

The installed video monitoring components are elements of the general mining plant video monitoring system.